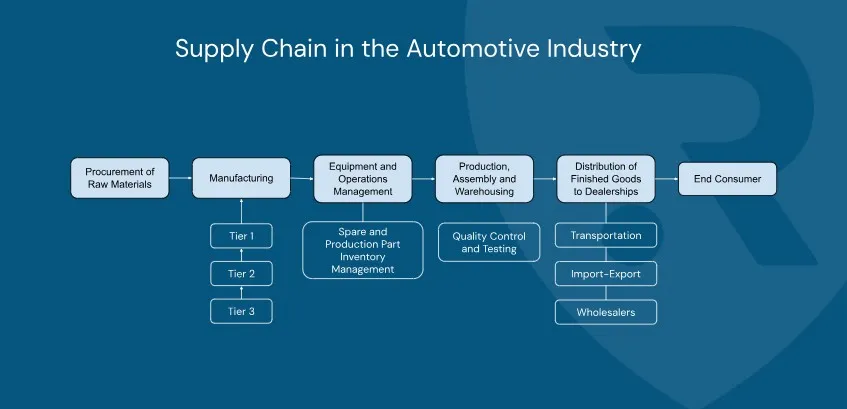

The major cyberattack that halted Jaguar Land Rover’s production for almost six weeks has exposed a hard truth: modern automotive manufacturing is deeply vulnerable to digital disruption.

From frozen assembly lines to supplier chaos and regional economic fallout, the incident showed how quickly a single IT failure can ripple across thousands of tightly-coupled supply-chain partners.

- Why this matters

Just-in-time workflows = zero buffer

Deep supplier networks = thousands of trust boundaries

IT/OT convergence = expanded attack surface

Software-driven vehicles = complex supply-chain exposure

- What manufacturers must prioritize

Zero Trust across IT & OT

Strong supplier security governance

Resilient operational architectures

Fast detection + safe restart playbooks

At RELIANOID, we’re focused on helping manufacturers reduce blast radius with high-performance proxies, strong session controls, hot-restart capabilities, and resilient traffic handling — allowing critical systems to stay operational even under stress.

The JLR incident wasn’t just costly — it was a systemic warning. Resilience is now an industrial strategy.

#CyberSecurity #Automotive #SupplyChain #ZeroTrust #Resilience #OTSecurity #ManufacturingSecurity #CyberResilience #RELIANOID